Active Heave Compensation for ROVs and Launch & Recovery Systems

Worried about damaging your ROV or TMS?

What is the best way to stabilize ROV operations in rough seas?

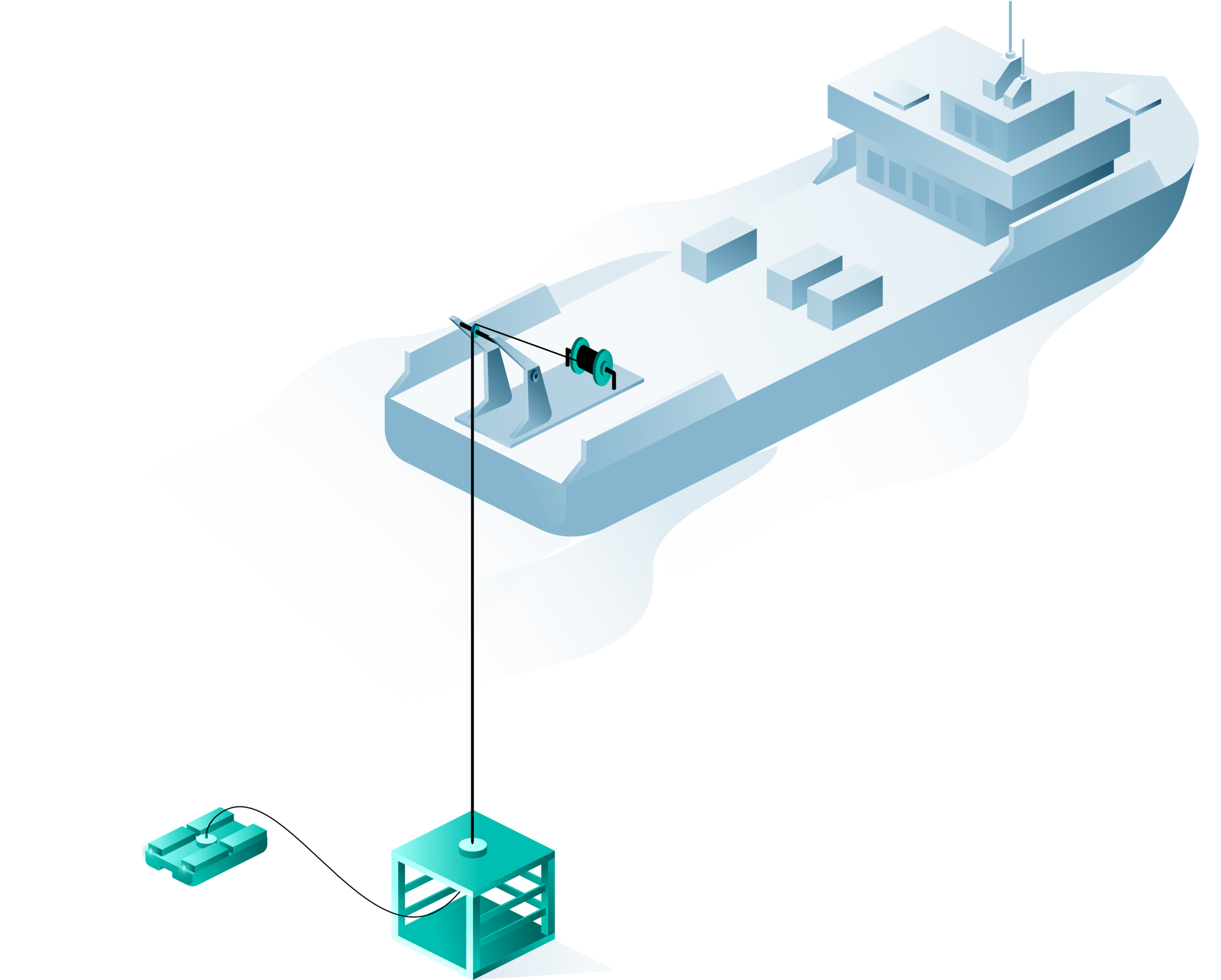

Using an Active Heave Compensation (AHC) system like Scantrol’s mTrack is the most effective way to stabilize ROVs. It removes vessel motion from the Tether Management System (TMS), ensuring safe deployment and recovery even in harsh sea conditions.

Why AHC is Essential for ROV Operations

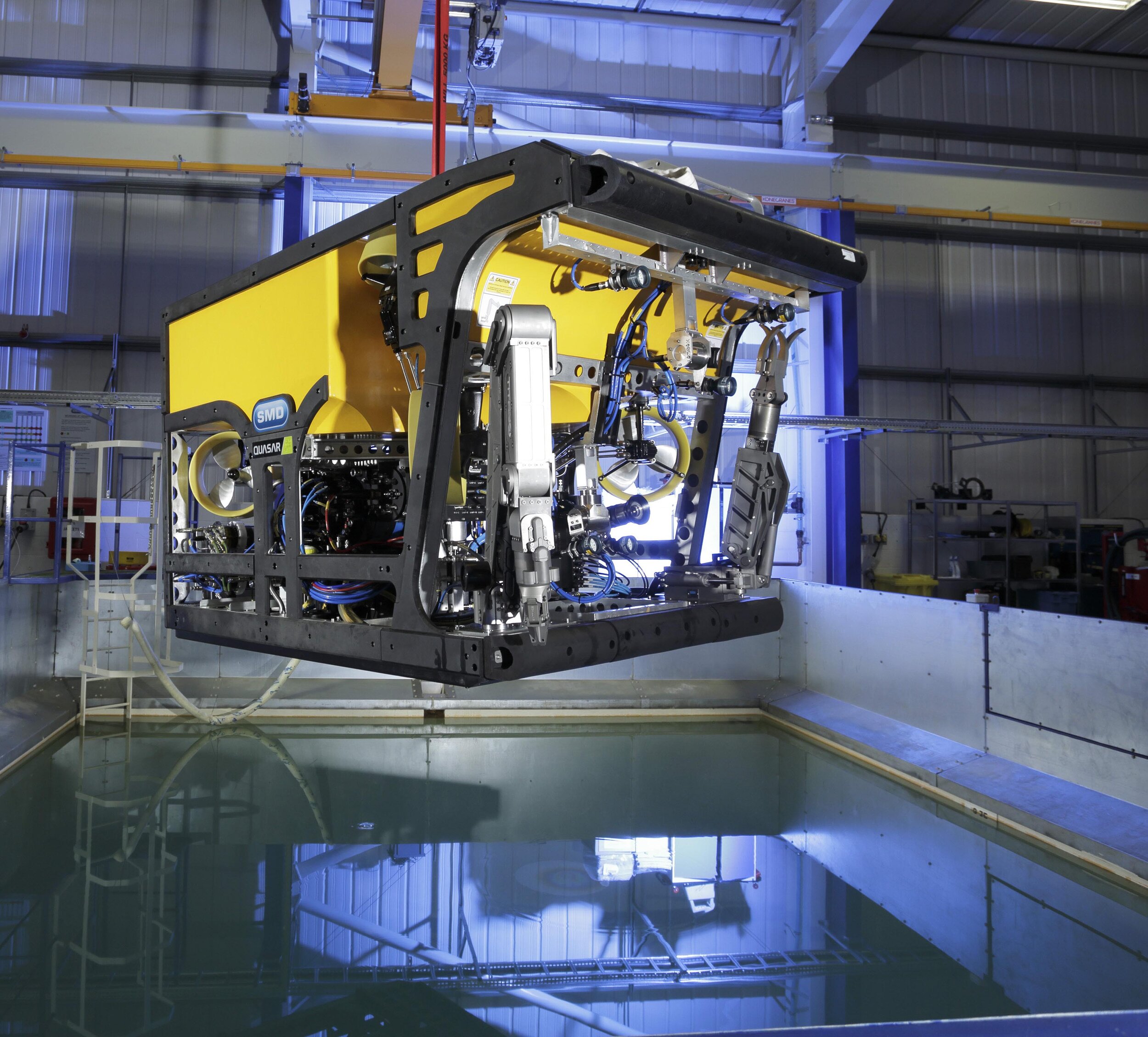

Remotely Operated Vehicle (ROV) is an underwater robot used for subsea operations. Controlled from Launch and Recovery System (LARS) on a surface vessel via an umbilical cable, ROVs are equipped with cameras, sensors, and robotic arms to perform tasks like pipeline inspection, equipment maintenance, and scientific sampling.

However, vessel motion due to waves impacts ROV performance, leading to damages, inefficiencies, safety risks, and increased operational costs. mTrack Active Heave Compensation (AHC) Controller stabilizes the Tether Management System (TMS) and counteracts vessel motion in real time. This ensures smoother operations, minimizes mechanical strain on umbilicals, and enhances overall safety and efficiency, even in rough weather conditions.

The Challenges in Work Class ROV Operations

Weather Dependency: Rough seas limit your operational window.

TMS Instability: Without compensation, the TMS moves unpredictably with the vessel, increasing docking risks.

Umbilical Stress: Excessive movement causes wear and tear on umbilicals, reducing their lifespan.

Damage risk: Sensitive ROV components can be damaged by sudden jerks or uncontrolled movement.

Delays and Downtime: Unstable conditions lead to lost time and increased cost.

Key Benefits of Scantrol AHC for ROVs

Increased Weather Window: Operate in higher sea states with more uptime.

Safe and Precise Docking: Keep your TMS stable, even with inexperienced operators.

Reduced Umbilical Wear: Anti-snatch function protects the ROV’s lifeline.

Cost-Effective Solution: No need for expensive sea trials, test and tune at dockside.

Free OTA: 24/7 Remote Support, maintenance, and training included.

Install mTrack AHC Controller and take the Vessel Motion out of the Equation

• Off-the-shelf AHC controller with integrated MRU.

• A game-changer that makes AHC affordable even for smaller winches and cranes used for subsea operations.

• Includes all the tools you need for easy installation and commissioning, no need for expensive experts.

Technical Features of mTrack AHC for ROVs

AHC

Maintains TMS stability during ROV launch and recovery.

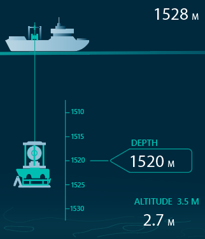

AUTO DEPTH

Automatically keeps your ROV or tow body at desired depth.

ANTI-SNATCH

Reduces peak loads on umbilicals, increasing lifetime.

WITHOUT TMS

AHC keeps your ROV stable even without a TMS.

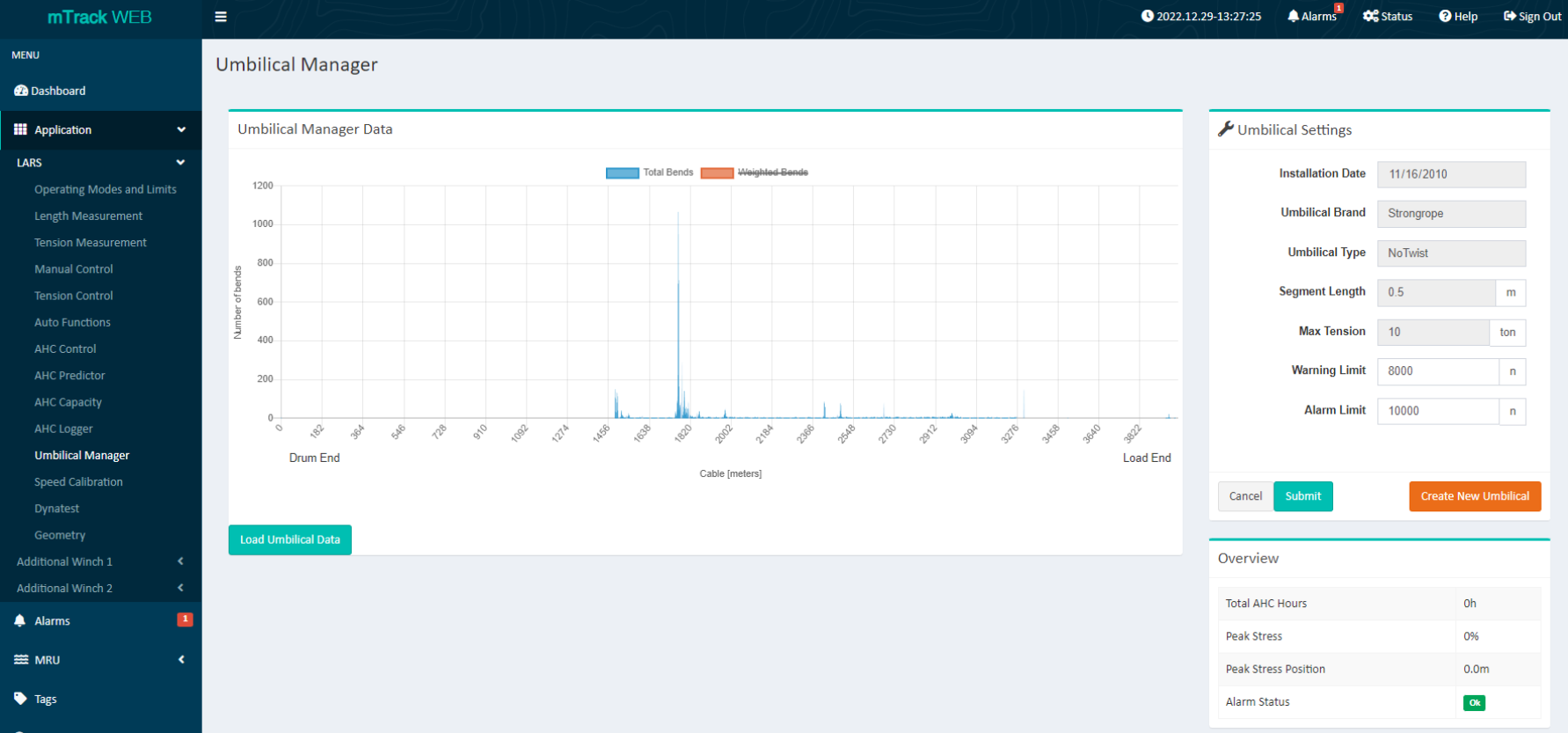

Umbilical Manager

Protects umbilicals from excessive strain, extending their lifespan and reducing maintenance costs.

Pre-configured for LARS

Quick plug-and-play setup for most launch & recovery systems, including electric and hydraulic winches.

Real-World Applications of Scantrol AHC

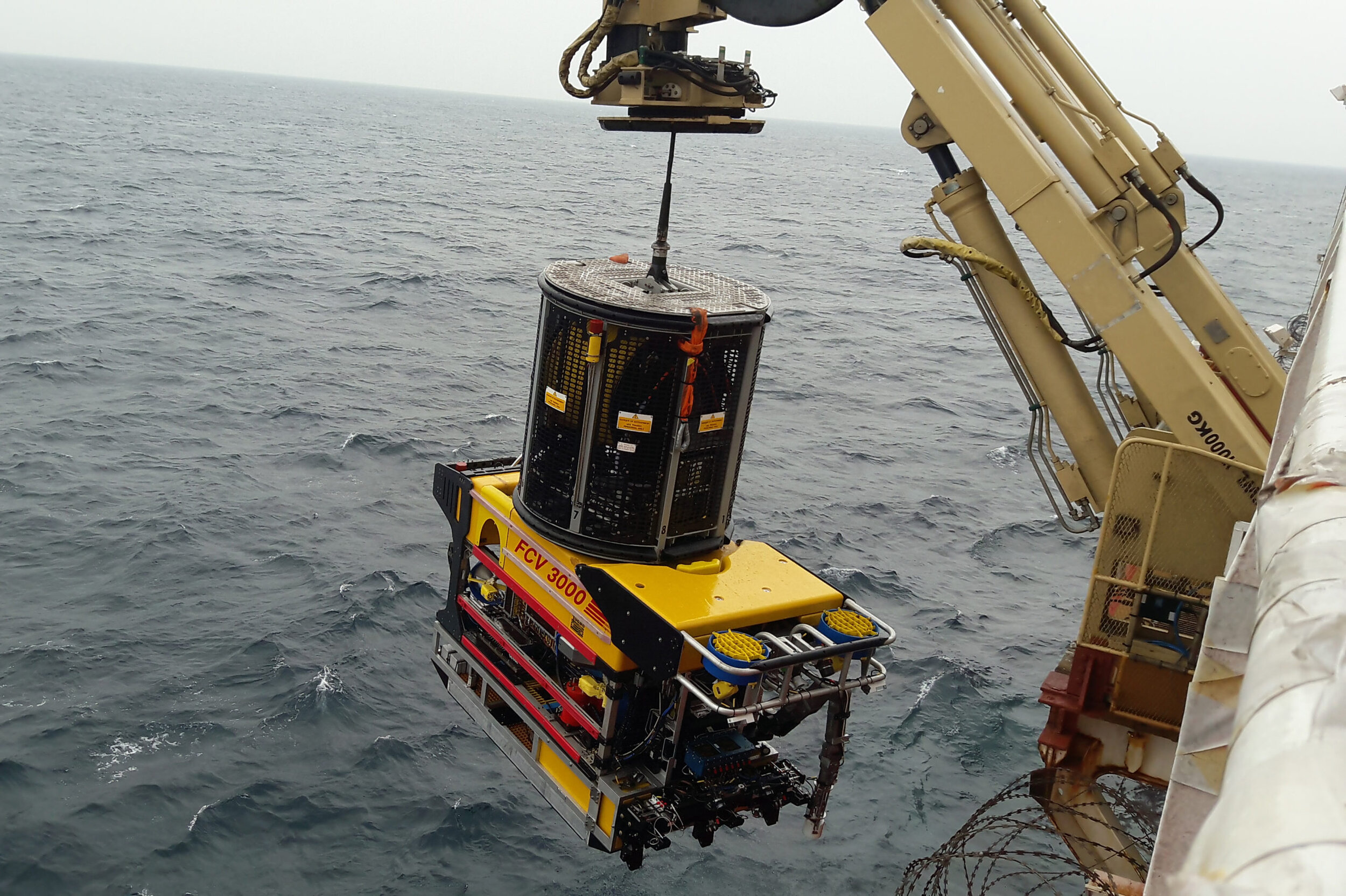

Many ROV operators worldwide have successfully retrofitted Scantrol AHC to existing Launch and Recovery Systems (LARS), enhancing stability and reducing downtime. Scantrol AHC is installed on new and upgraded winches from a range of recognized LARS manufacturers: Dynacon, Fugro, Hydramec, Ennsub, Odim, Lawson, Lidans, Evotec, SMD, Ibercisa, Kongsberg and Rolls-Royce.

Good results and high performance were witnessed by the client . The system is now operational and all feedback from the client has been positive

Danny Church, Managing Director at Hydramec.

“With Scantrol AHC the ROV pilot will be able to maintain the position of the TMS unit while focusing on docking and undocking operation the ROV in order to prevent any disastrous situation of damaging the delicate tether, which is the “life line” of any ROV system.”

- William Lee, Service Line Manager at Fugro Subsea Technologies in Singapore,

“With this equipment, we reduce weather-related downtime, ensuring the achieved value pays back the investment spent on the system.”

- Hans Martin Gravdal, former CEO of Swire Seabed

How to Retrofit mTrack to Existing Winches

Many winches are suitable for AHC operation, reuse of your winch represents a major cost reduction compared to buying a new winch and results in a reduced carbon footprint.

We can help you determine if your winch is suitable for AHC.

Interested in upgrading your ROV operations?

Contact us today to discuss your project. Our experts will help you determine the best AHC solution for your system.

Suzy Zhu

International Sales Manager

Email: suzy@scantrol.com

Phone: +47 465 20 370

Cato Johansen

CEO

Email: cato@scantrol.com

Phone: +47 479 60 500